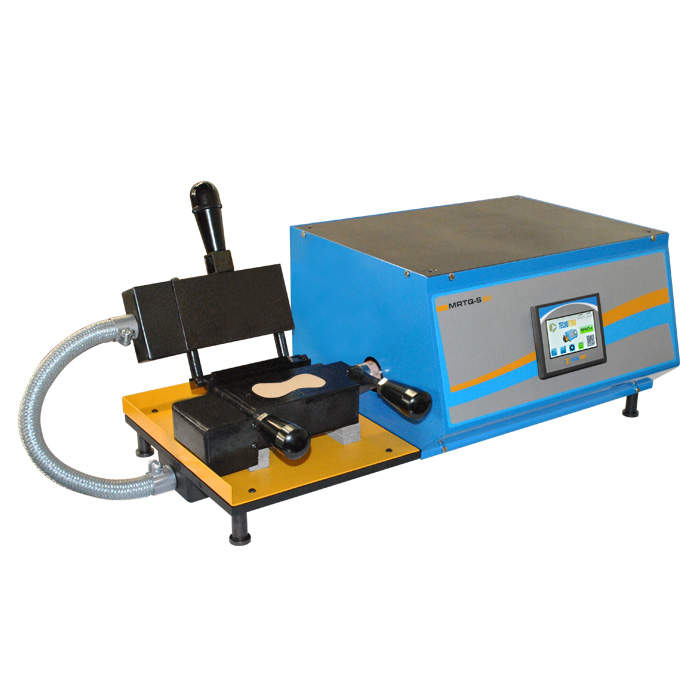

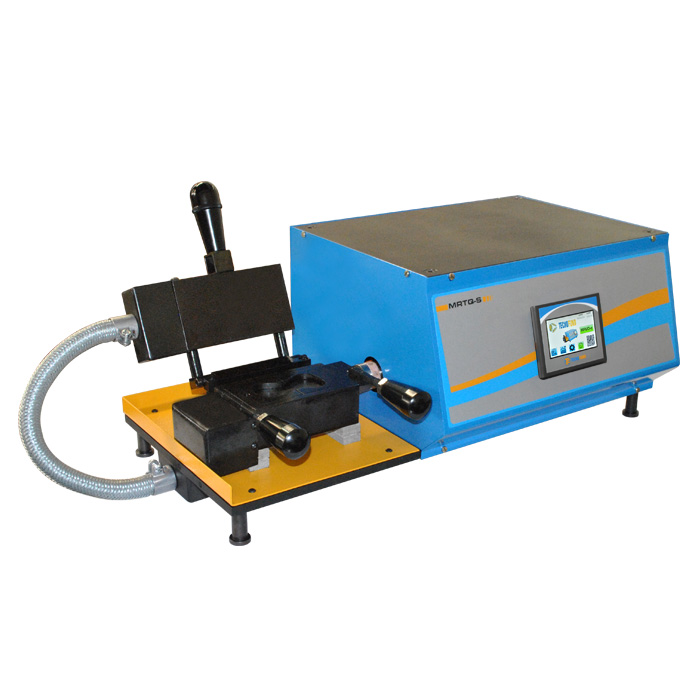

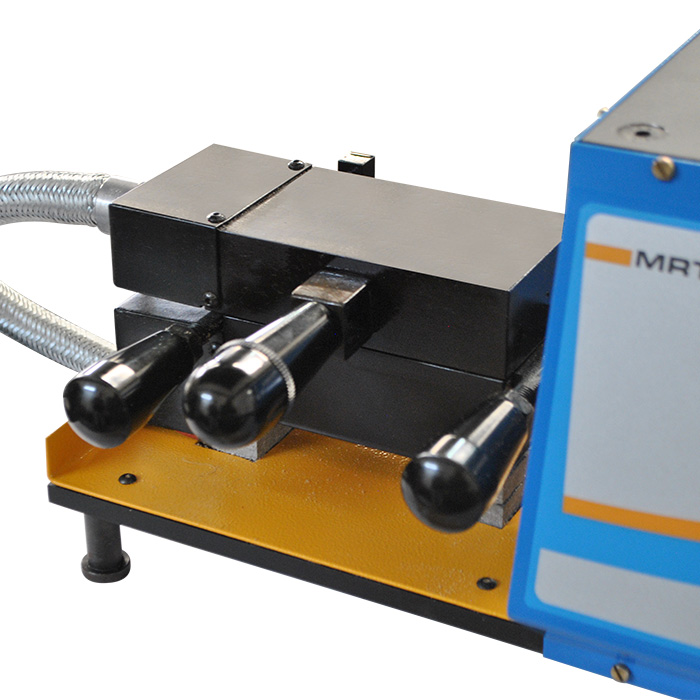

SHELL/CRONING SAND LABORATORY

Foundry EquipmentModel MRTQ-S-e

SPECIFICATIONS

- Measuring range: 0 – 6000 N/cm2 (0 – 850 psi)

- Range resolution: 0,1 N/cm2 (0,1 psi)

- Temperatura control: 0 to 760 C

- Cure timer: 0 to 9,99 min.

- Power requirements: 230 V / 50-60 Hz (820 W)

- Compressed air required: 6 bar (85 psi)

- Weight: 48 kg (106 lb)

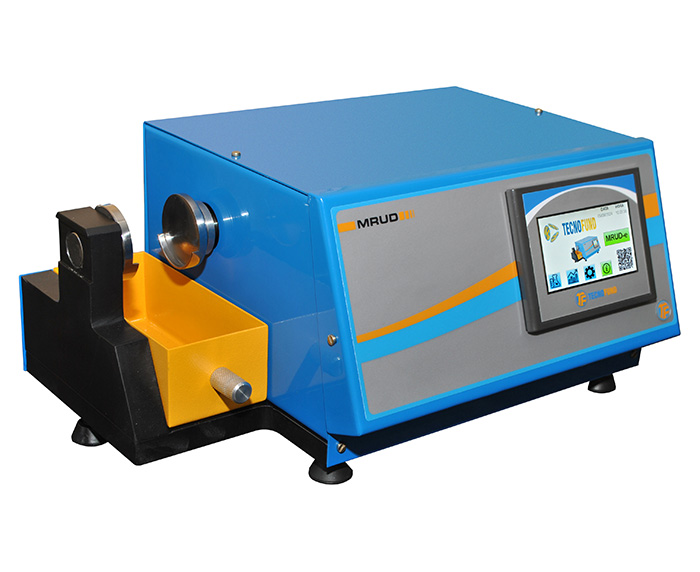

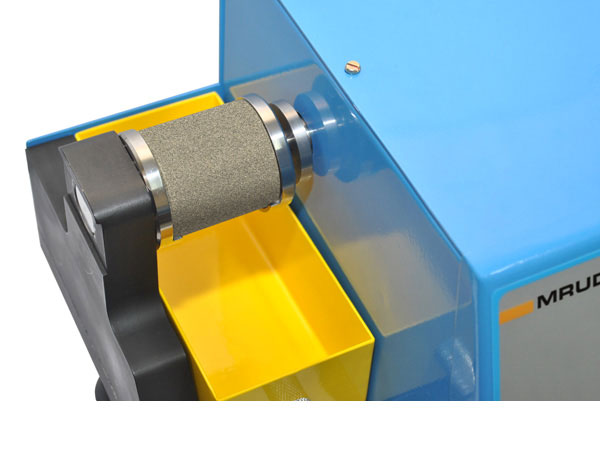

Model MRUD-e

ELECTRONIC UNIVERSAL SAND COMPRESSIVE STRENGH

Performs the compression tests green.

SPECIFICATIONS

- Measuring range: 0 – 99,00 N/cm2 (compressive strength)

- Range resolution: 0,01 N/cm2

- Uses metric ou AFS specimens

- Includes compressive strength accessories

- Power requirements: 230 V / 50-60 Hz / 150w

- Results in N/cm2, Kgf/cm2 or psi

- Print data in label or sent to the PC via cable

- Dimensions: 45 x 25 x 23cm

- Weight: 26 kg (57 lb)

OPTIONAL PRINTER (self adhesive label Model)

Model PER-e

ELECTRONIC PERMMETER

For determination the permeability of clay and/or chemically bonded sand specimens.

SPECIFICATIONS

- Measuring range: 0 – 999 cm4/g.min. (AFS)

- Range resolution: 0,1 cm4/g.min. (AFS)

- Uses Metric ou AFS specimens

- Calibration standard included

- Power requirements: 230 V / 50-60 Hz

- Dimensions: 26 x 54 x 40cm

- Weight: 22 kg (48 lb)

ACCESSORIES:

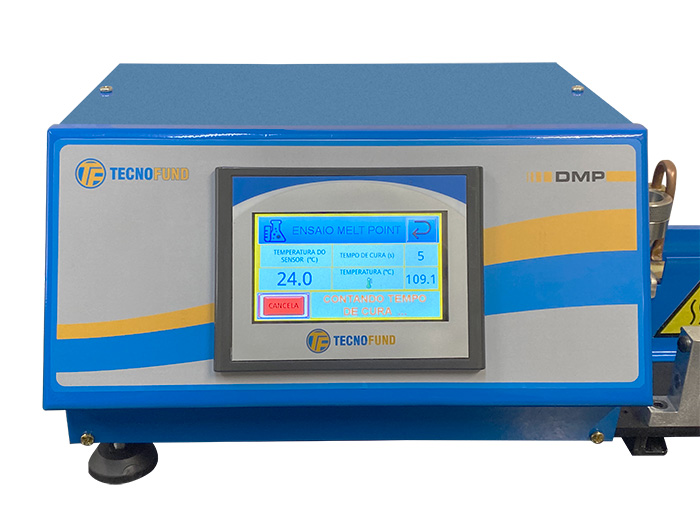

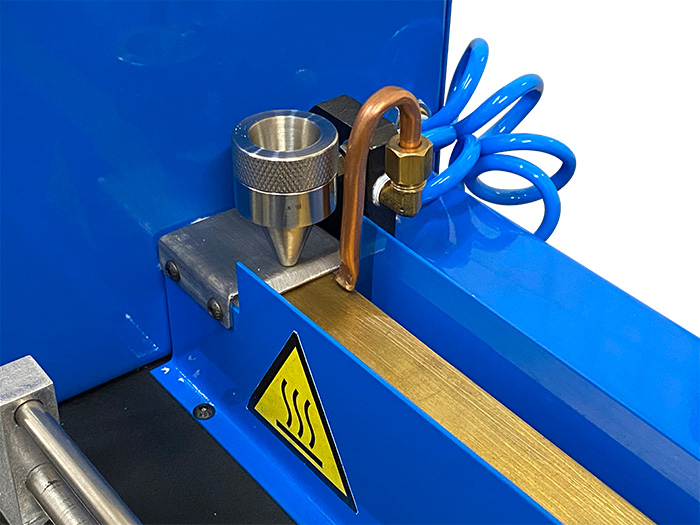

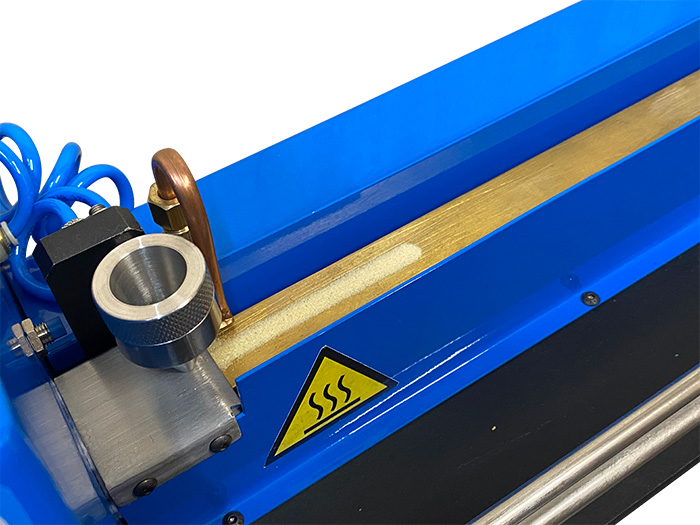

Model DMP

MELT POINT TESTER- SHELL SANDS

This test instrument measures the melt point or stick point of shell resin coated sands.

SPECIFICATIONS

- Automatic advance and return to the distribution of sand on top bar, automatic blow to detect the melt point

- Has a high-precision thermocouple tip.

- Digitals controls:

– cure timer: 0 to 99,9 minutes

– test temperature: 0 to 200° C

– heated bar temperature: 0 to 200° C - Power requirements: 220 V / 50-60 Hz

- Compressed air required: 4 – 6 bar (56 – 85 psi)

- Weight: 40 kg (88 lb)

Model DPB

PEEL BACK TESTER – SHELL SANDS

This test instrument measures the peel back test of shell resin coated sands.

SPECIFICATIONS

- Automatic spin and return of the heated disc

- Digitals controls:

– cure timer: 0 to 99,9 minutes

– test temperature: 0 to 450° C - Includes stainless steel tray

- Power requirements: 220 V / 50-60 Hz

- Weight: 25 kg (55 lb)

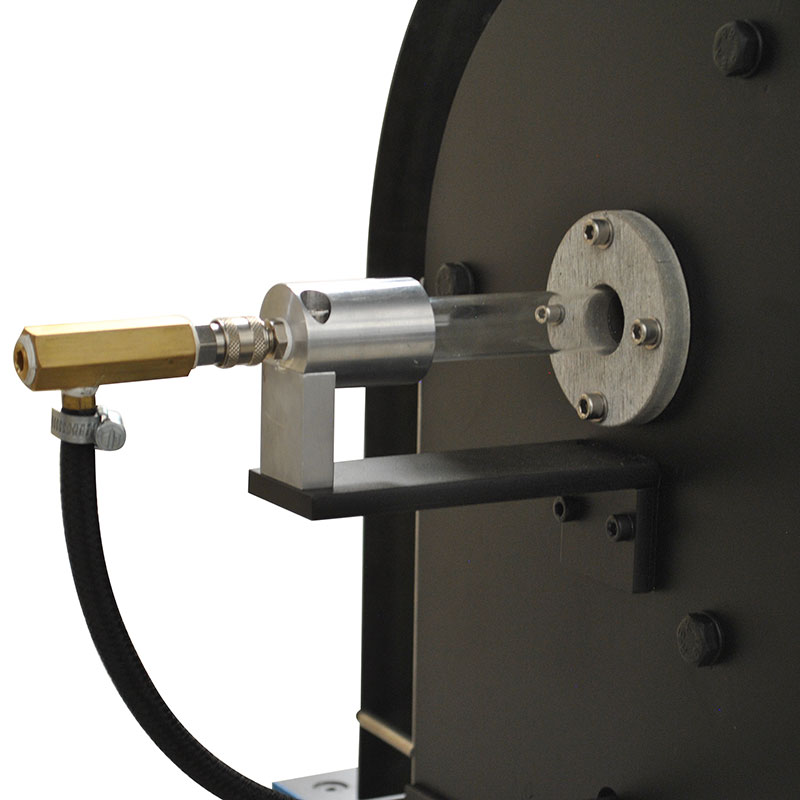

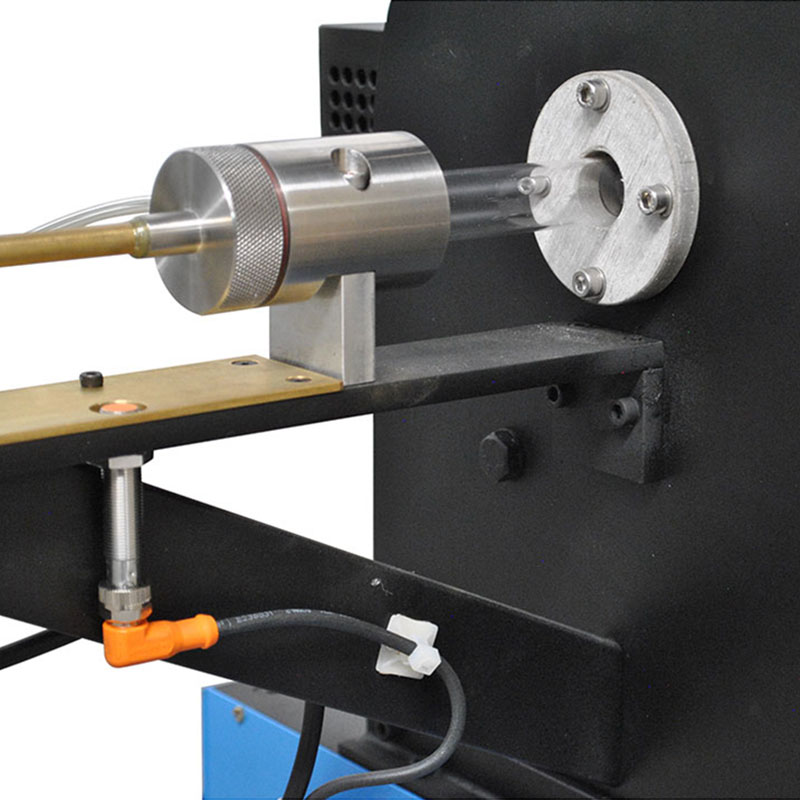

Model DVG-e

GAS PRESSURE AND VOLUME MEASURING DEVICE

This device serves to measure the gas pressure and, indirectly, the gas volume (the sum of all gasses) on various foundry materials.

With a special software (included) the pressure diagram can be displayed on a computer.

SPECIFICATIONS

- Fully electronic equipment indicating via IHM with temperature control, pressure and test time

- Digitals controls:

– Gas pressure range: 0 -250 mbar (0 – 3,60 psi)

– Test temperature: 0 to 1100° C - Cylindrical furnace with metal resistors and isolated with ceramic blanket.

- Nitrogen gas required: 2 -4 bar (28 – 56 psi)

- Power requirements: 220 V / 50-60 Hz / 1500 w

- Dimensions: 35 x 80 x 80cm

- Weight: 45 kg (99 lb)

Model DDM

CORE HARDNESS TESTER

A practical pocket-sized instrument for measuring the surface and sub-surface hardness of baked cores and dry sand molds.

SPECIFICATIONS

- Measuring range: 0 – 100 AFS

- Direct reding with lock system

- Uses 1-SR44 Button Cell Battery

- Weight: 0,5 kg (1,10 lb)